l Intuitive touch screen operation, which is on the rotary operator.

l Air over oil cylinder gives large clamping force for larger part.

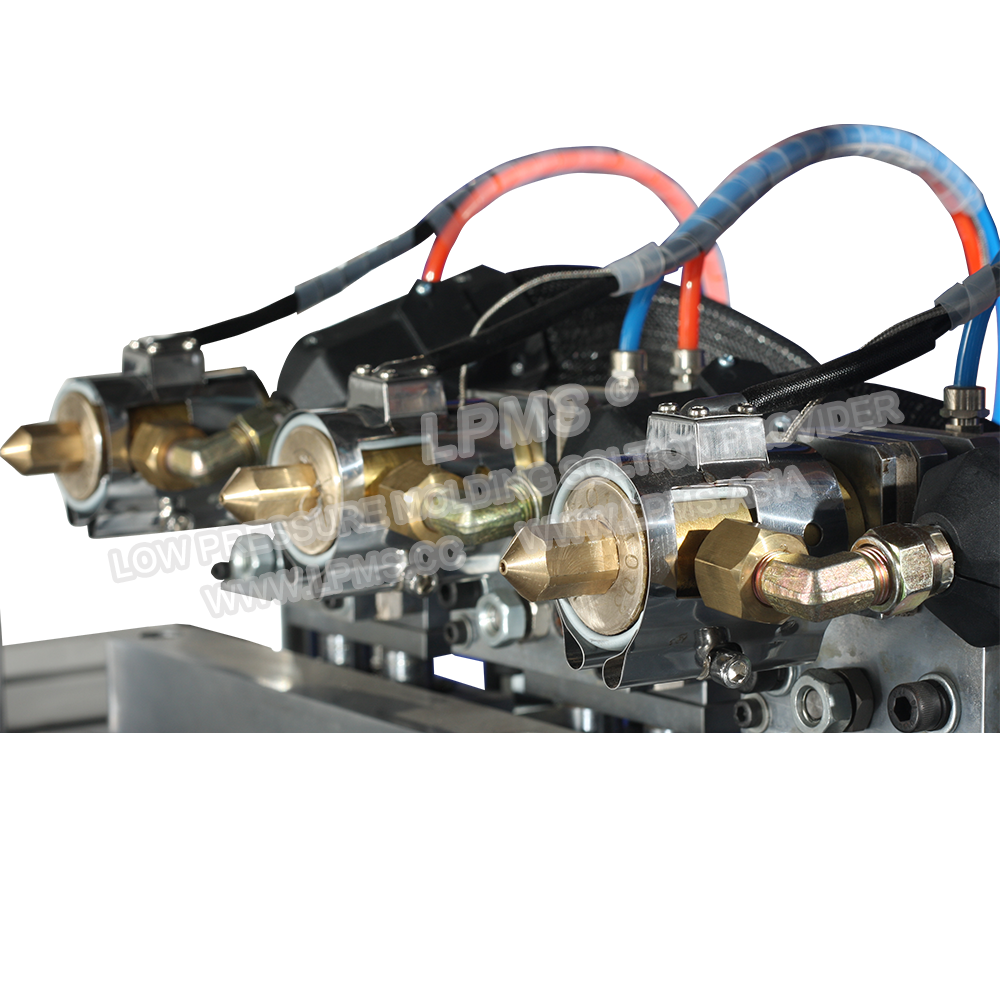

l Two independent injection guns.

l Dual 7 liter melting tanks. Run different molding materials at the same time.

l LPMS specially designed melt-on-demand tank can melt down the resin swiftly and evenly.

l The gear pump is made of hard-wearing material,which is stable,injection volume accuracy ±0.1g,maximum shot size is 5g/s.

l Injection pressure range 1~50kg, which is controlled by pneumatic safety valve. LPMS also have option like electronic safety valve, which means the injection pressure can be set more precisely from the PLC.

l Linear scale it’s precise for mold clamping, does not need to adjust the reed switch position.

l Six thermal control zones for precise melt control.

l Light curtain and dual palm buttons for operator safety.

Application

Application scope:

Our machines are engineered for low pressure molding applications using specialty resins to overmold delicate parts. Applications span many industries including: automotive, PCBA,coil,fiber-optic,LED lighting, wire and cable,and electronics.

Specification

Machine Size mm | 1120 mm x 1000 mm x 2310 mm / 1200 Kgs 44.09 in x 39.37 in x 90.94 in / 2646 lbs |

Work Station Height | 860 mm | 33.86 in |

Plant View | 2000 mm x2000mm | 78.74 in |

Packing Size | 1310 mm x 1150 mm x 2330 mm / 1300 Kgs 51.57 in x 45.28 in x 91.73 in / 2866 lbs |

Melting Tank Model &Q'ty1 | LPMS 500B -5 Liter x 2 or more |

Auto Feed | Optional |

Gun Model & Tip Angle | LPMS-G02 / 36.4° |

Heated Hose Model & Q'ty2 | LPMS-H16J x 2 or more |

Electricity3 | 200-240VAC / 1Phase / 50 or 60Hz |

Temperature Control Zones | 6 or more |

Temperature Range4 | Ambient Up To 446℉ |

Max. Power | 9 Kw or more |

Min. Air Pressure | 0.5 MPa | 73Psi |

Air Consumption | 0.1m3 / min | 3.5ft3 / min |

Clamping Device | Air Over Oil Cylinder |

Clamping Force | Max.5 Tons or optional 10Tons |

Clamping Stroke (mm) | 150 mm | 5.91 in |

Control System | PLC+7 in HMI |

Safety Protection | Light Curtain |

LPMS Standard Mold Set Size | N/A |

Max. Mold Set Size | 600 mm x 180 mm x 275 mm | 23.62 in x 70.87 in x 10.83 in |

Max. Part Size | 500 mm x 70 mm x 10 mm | 19.69 in x 2.76 in x 0.39 in |

Dimension

Machine dimension

Mold set dimension

Video

Copyright ? 2015-2018 LPMS International Ltd. All Rights Reserved.